Finger-Jointed Pine vs MDF Mouldings

Which timber moulding should you opt for in your next project? Let’s take at look at some pros and cons.

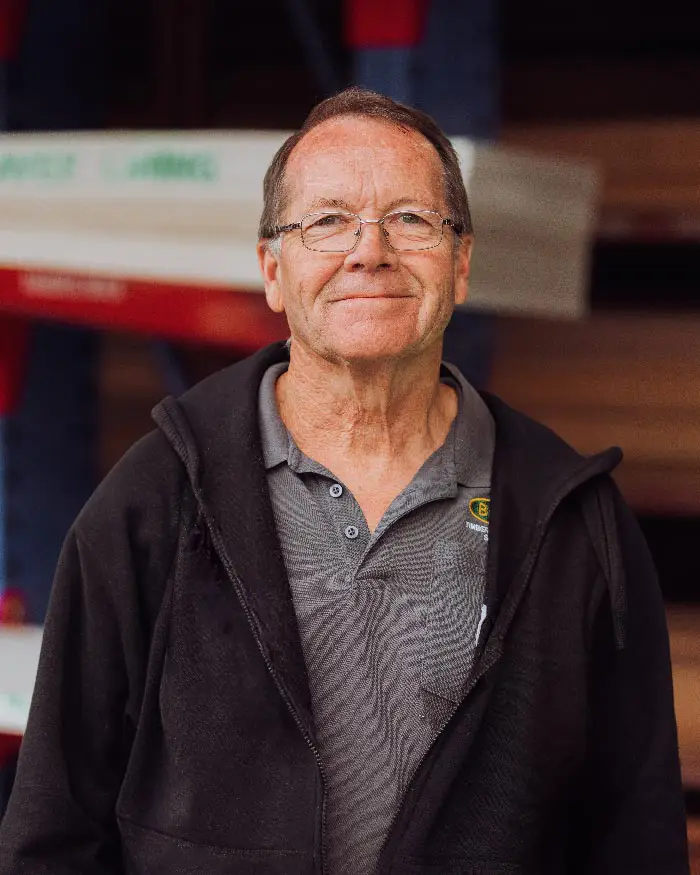

There’s no doubt that Rob Paterson is a highly respected member of the Bone Timber for more reasons than one. As Technical Sales Support, Rob plays the pivotal role of doing estimates and quotes for builds across South Australia — something his team trusts him with wholeheartedly.

The former carpenter and now qualified building technician has racked up 26 years with the team so far, and his attitude that he “treats it as a privilege” speaks volumes about how much he loves helping our customers and now mentoring many of our staff.

Rob shared a bit about his years of experience with us …

Well, it was thanks to my kids, actually. I was originally working as a carpenter (and then a production manager) at a company that closed down. During that time off, I was taking the kids to The Royal Show on the train and they saw the Bone Timber sign and they told me to ring up. I had a fantastic chat with Colin (the secretary) and Howard Bone and started out with quoting before they realised I could do the estimating side of things, too.

I like working directly with the builders, architects and engineers, and I work mainly on residential jobs.

I’ll go on-site to measure up and then organise trusses for the builders through an external company. I enjoy counting up how much timber is involved, then doing up a quote. There’s a lot of jobs on, so we also use external estimators, and they’re really great to work with, too.

And working with good people makes a difference. I spend so much time with them, so it’s good to enjoy coming to work. I treat it as a privilege, actually.

Yes, after building floor, wall and roof frames (including second fix), I understand all the terminology that’s involved in designing and estimating in each particular house design. It’s a lot of technical knowledge on sizing the beams, making sure it’s the right specifications. A lot of factors come into play, like figuring out a beam design and wall bracing and tie downs — I find that interesting. We’ve got computer programs that we use and books to match things up to the timber framing code, but I like putting that all together.

I enjoy it — I try to guide them where I can. Two of the younger guys are doing postgraduate courses now, which is a similar sort of skill set to what I do, so they’ll learn the estimating side of things.

I also brought in a model house, which shows all the timber used in a full build — the floors, the walls and the roof. I went through it all with the whole team and I think everyone found it helpful. I think it’s a good thing to keep out on display because it shows you pretty clearly how things are put together.

Timber can be visually stress-graded according to the size of their strength-reducing characteristics, knots, sloping grain, density etc and all four surfaces are assessed by this method. Visual grading relies to the extent upon human judgement.

Mechanical stress grading is a method of grading in a machine, which applies a non-destructive bending load at intervals along the timber’s length and measures the deflection in each case.

My family. I’ve got a daughter in Melbourne, two sons in Queensland and two grandchildren, who are now 16 and 18. I also love fishing and Australian Rules Football — and when I can, I get over to Victoria to see the Essendon Bombers.

Which timber moulding should you opt for in your next project? Let’s take at look at some pros and cons.

Meet Paul Aitchison – our resident Timber Expert and Service Guru here to shape your perfect project.

20 years as a tradie followed by 31 years with Bone Timber, hear what Gary Gray thinks makes Bone special.

Bone Timber © 2026 All rights reserved